Difference between revisions of "Msc2G7:Expert3"

(→Drive) |

Gary Chang (Talk | contribs) |

||

| (31 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

__NOTOC__ __NOTITLE__ | __NOTOC__ __NOTITLE__ | ||

| + | |||

==Motors & Sensors== | ==Motors & Sensors== | ||

<div style="height:30px; width: 850px; margin:0px; padding: 0px; padding-top: 20px; border: 0px;"> | <div style="height:30px; width: 850px; margin:0px; padding: 0px; padding-top: 20px; border: 0px;"> | ||

| − | <div style="float:left; width: | + | <div style="float:left; width: 90px; height 30px; border: 1px solid #aaa; margin-right:8px; " align="center"> |

| − | [[Msc2G7:Frontpage|'''BOP''']] | + | [[Msc2G7:Frontpage|''' BOP ''']] |

</div> | </div> | ||

| − | <div style="float:left; width: | + | <div style="float:left; width: 120px; height 30px; border: 1px solid #aaa; margin-right:8px" align="center"> |

| − | [[Msc2G7: | + | [[Msc2G7:Expert5|''' Weekly Planning ''']] |

</div> | </div> | ||

| − | <div style="float:left; width: | + | <div style="float:left; width: 130px; height 30px; border: 1px solid #aaa; margin-right:8px; " align="center"> |

| − | [[Msc2G7: | + | [[Msc2G7:Expert1|''' Joints&Calculations ''']] |

</div> | </div> | ||

| − | <div style="float:left; width: | + | <div style="float:left; width: 120px; height 30px; border: 1px solid #aaa; margin-right:8px;" align="center"> |

| − | [[Msc2G7: | + | [[Msc2G7:Expert3|''' Motors&Sensors ''']] |

</div> | </div> | ||

| − | <div style="float:left; width: | + | <div style="float:left; width: 90px; height 30px; border: 1px solid #aaa; margin-right:8px" align="center"> |

| − | [[Msc2G7: | + | [[Msc2G7:Expert4|''' Control ''']] |

| + | </div> | ||

| + | <div style="float:left; width: 130px; height 30px; border: 1px solid #aaa; margin-right:8px" align="center"> | ||

| + | [[Msc2G7:Expert6|''' Plenary Session 2 ''']] | ||

| + | </div> | ||

| + | <div style="float:left; width: 90px; height 30px; border: 1px solid #aaa;" align="center"> | ||

| + | [[Msc2G7:Questions|''' Questions ''']] | ||

</div> | </div> | ||

</div><br> | </div><br> | ||

| − | == ''' | + | ==Servo testing== |

| + | Servo testing 250gr on 30cm arm. Testing the power demand. <br/> | ||

| + | http://re.hyperbody.nl/pdf/Film1.2.mp4 <br/> | ||

| + | Servo testing 250gr on 40cm arm. <br/> | ||

| + | http://re.hyperbody.nl/pdf/Film2_2.mp4 | ||

| + | |||

| + | == 6/5 computer, sensor and connection choices == | ||

| + | |||

| + | '''1. One joint with sensor working ''' <br/> | ||

| + | Raspberry pi/Arduino control motor with sensor | ||

| + | |||

| + | |||

| + | '''2. Two (Micro)Computers Communicating ''' | ||

| + | ethernet/bluetooth | ||

| + | |||

| + | '''3. Advanced control''' | ||

| + | Consensus Algorithm | ||

| + | |||

| + | ==25/3 Adapt servos == | ||

| + | [[File:IMG_2917.JPG|300px]] | ||

| + | <br/> | ||

| + | <br/> | ||

| + | The brown wired element on the right is the potentio meter. That measures the angle of the output axle of the motor. The turning angle of the meter is limited to less than 360 degrees. So that causes a problem when putting any gears on that axle to increase torque. The meter has to be replaced to the good axle of the right measurements. | ||

| + | |||

| + | == 11/3 Type of Motor Decisions == | ||

| + | |||

| + | Based on some requirements for the motor, the decision was made to use a Servo Motor, instead of a Stepper Motor or a DC Motor. | ||

| + | |||

| + | The requirements were the following: | ||

| + | |||

| + | # The position controllability of the axle of the motor | ||

| + | # A high power/weight ratio | ||

| + | # High accurately placed at a desired angle of the axle | ||

| + | # Being able to stall for some time | ||

| + | # Being low cost | ||

| + | # Availability of using a battery to power the motor | ||

| + | |||

| + | |||

| + | In the next 2 documents the decision of the Servo Motor is being explained further | ||

| + | |||

| + | [https://www.dropbox.com/s/vqyap2iolt25r9n/Pve%20motoren%20uitgebreid.docx?dl=0] | ||

| + | |||

| + | [https://www.dropbox.com/s/yaukn9b1psq8r9r/PvE%20motoren.xlsx?dl=0] | ||

| + | |||

| + | == 5/3 Arduino testing == | ||

| + | |||

| + | |||

| + | [[File:FullSizeRender.jpg|400px]] | ||

| + | Attempt to connect and control dynamixel 12a+ | ||

| + | |||

| + | [[File:IMG 2840.JPG|400px]] | ||

| + | Dynamixel control module/chip sn74ls241 | ||

| + | |||

| + | == 4/3 Drive == | ||

The most influential decision for the design of the joint is the way the joint is driven. In this document we argue the different drive and the best suitable on for our design needs. | The most influential decision for the design of the joint is the way the joint is driven. In this document we argue the different drive and the best suitable on for our design needs. | ||

| Line 39: | Line 99: | ||

'''Mechanical''' | '''Mechanical''' | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Powerfull, but not sustainable and sharing energy enhances the risk of explosions. | |

| − | |||

| − | + | '''Hydraulic ''' | |

| − | + | Unlimited torque, but efficiency starts at high weight. Also extra weigth of the fluids. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | '''Pneumatic ''' | |

| − | + | Good power/weight ratio, but low forces and hard to share energy. | |

| + | '''Electrical (Best suitable for our design)''' | ||

| − | + | The most suitable option. Powerfull and light. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| Line 111: | Line 123: | ||

http://www.rcheliwiki.com/Power_to_weight_ratio | http://www.rcheliwiki.com/Power_to_weight_ratio | ||

http://www.inmoco.co.uk/electro-mechanical_vs_pneumatic_actuators | http://www.inmoco.co.uk/electro-mechanical_vs_pneumatic_actuators | ||

| + | |||

---- | ---- | ||

| + | With the support of the Culture Programme of the EU.<br> | ||

| + | [[File:EU_flag.jpg|420px]][[File:META_logo.jpg|420px]] | ||

Latest revision as of 10:48, 23 March 2016

Motors & Sensors

Servo testing

Servo testing 250gr on 30cm arm. Testing the power demand.

http://re.hyperbody.nl/pdf/Film1.2.mp4

Servo testing 250gr on 40cm arm.

http://re.hyperbody.nl/pdf/Film2_2.mp4

6/5 computer, sensor and connection choices

1. One joint with sensor working

Raspberry pi/Arduino control motor with sensor

2. Two (Micro)Computers Communicating

ethernet/bluetooth

3. Advanced control Consensus Algorithm

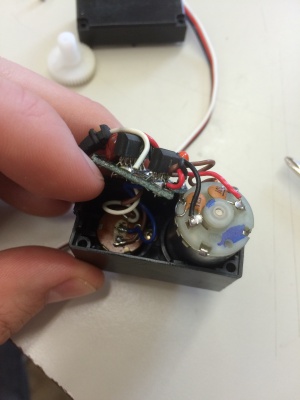

25/3 Adapt servos

The brown wired element on the right is the potentio meter. That measures the angle of the output axle of the motor. The turning angle of the meter is limited to less than 360 degrees. So that causes a problem when putting any gears on that axle to increase torque. The meter has to be replaced to the good axle of the right measurements.

11/3 Type of Motor Decisions

Based on some requirements for the motor, the decision was made to use a Servo Motor, instead of a Stepper Motor or a DC Motor.

The requirements were the following:

- The position controllability of the axle of the motor

- A high power/weight ratio

- High accurately placed at a desired angle of the axle

- Being able to stall for some time

- Being low cost

- Availability of using a battery to power the motor

In the next 2 documents the decision of the Servo Motor is being explained further

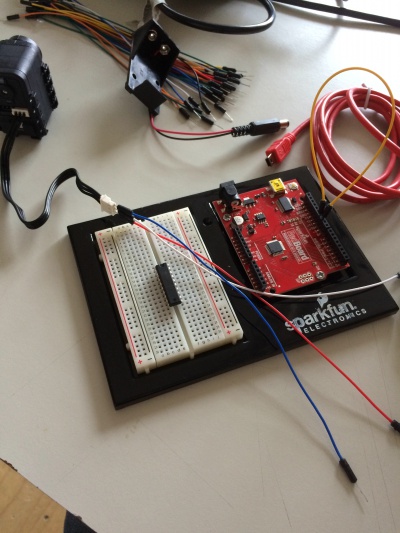

5/3 Arduino testing

Attempt to connect and control dynamixel 12a+

Attempt to connect and control dynamixel 12a+

4/3 Drive

The most influential decision for the design of the joint is the way the joint is driven. In this document we argue the different drive and the best suitable on for our design needs.

Criteria for the drive

- Handle high torques/forces (or high speed with a gearbox)

- Power/weight ratio

- Accurately controllable

- Size

- Sharing energy

- Maintaining position

- (Degrees of freedom (+/- 180°) (actually possible for every drive))

- Accessible for testing

The 4 Differtent Drives

Mechanical

Powerfull, but not sustainable and sharing energy enhances the risk of explosions.

Hydraulic

Unlimited torque, but efficiency starts at high weight. Also extra weigth of the fluids.

Pneumatic

Good power/weight ratio, but low forces and hard to share energy.

Electrical (Best suitable for our design)

The most suitable option. Powerfull and light.

http://www.designnews.com/document.asp?doc_id=230452

http://en.wikipedia.org/wiki/Power-to-weight_ratio

http://www.rcheliwiki.com/Power_to_weight_ratio

http://www.inmoco.co.uk/electro-mechanical_vs_pneumatic_actuators