Difference between revisions of "Msc2G7:Expert3"

| Line 64: | Line 64: | ||

http://www.inmoco.co.uk/electro-mechanical_vs_pneumatic_actuators | http://www.inmoco.co.uk/electro-mechanical_vs_pneumatic_actuators | ||

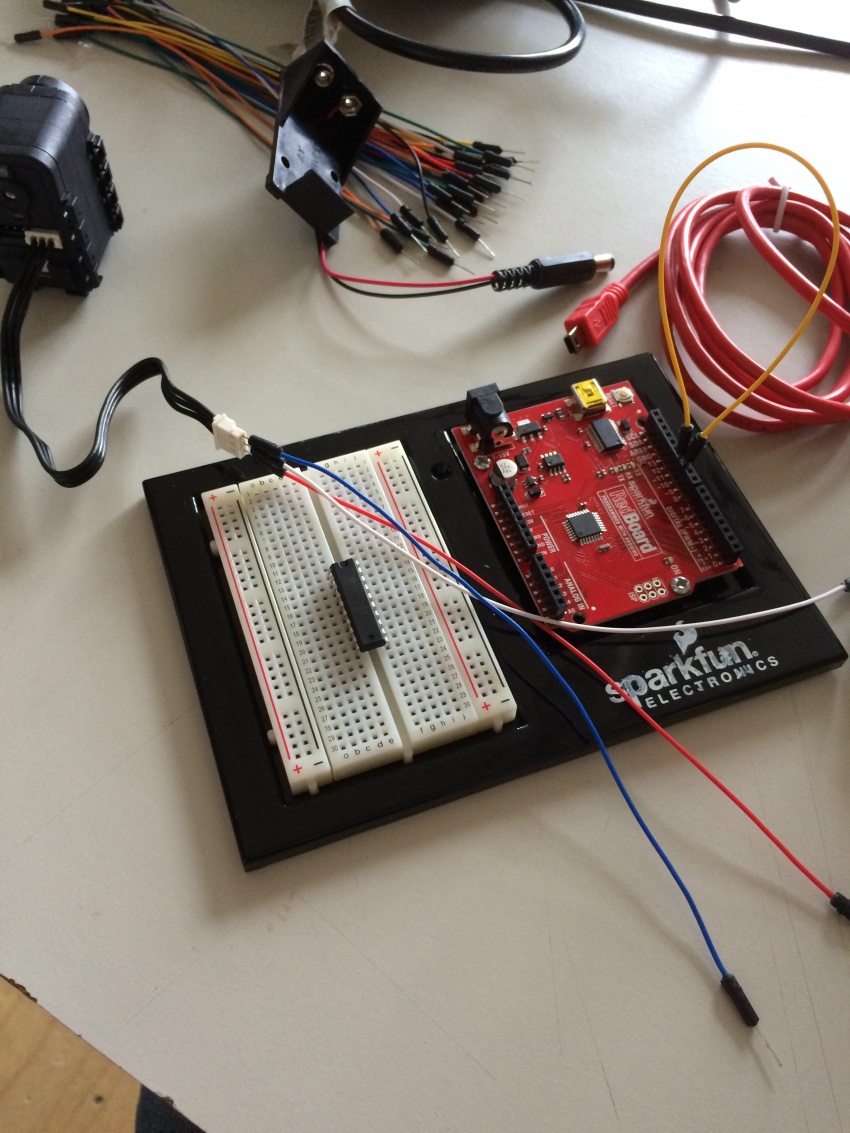

| − | [[File:IMG 2840.JPG] | + | [[File:IMG 2840.JPG|850px]] |

---- | ---- | ||

Revision as of 12:42, 11 March 2015

Motors & Sensors

4/3 Drive

The most influential decision for the design of the joint is the way the joint is driven. In this document we argue the different drive and the best suitable on for our design needs.

Criteria for the drive

- Handle high torques/forces (or high speed with a gearbox)

- Power/weight ratio

- Accurately controllable

- Size

- Sharing energy

- Maintaining position

- (Degrees of freedom (+/- 180°) (actually possible for every drive))

- Accessible for testing

The 4 Differtent Drives

Mechanical

Powerfull, but not sustainable and sharing energy enhances the risk of explosions.

Hydraulic

Unlimited torque, but efficiency starts at high weight. Also extra weigth of the fluids.

Pneumatic

Good power/weight ratio, but low forces and hard to share energy.

Electrical (Best suitable for our design)

The most suitable option. Powerfull and light.

http://www.designnews.com/document.asp?doc_id=230452

http://en.wikipedia.org/wiki/Power-to-weight_ratio

http://www.rcheliwiki.com/Power_to_weight_ratio

http://www.inmoco.co.uk/electro-mechanical_vs_pneumatic_actuators