Difference between revisions of "Msc2workshop:workshop07"

| Line 2: | Line 2: | ||

== ''' “Morphodynamical approaches for fabrication and interactive design” ''' == | == ''' “Morphodynamical approaches for fabrication and interactive design” ''' == | ||

<html> | <html> | ||

| − | <iframe width=" | + | <iframe width="750" height="600" src="https://www.youtube.com/embed/videoseries?list=PLmnBQW0k0x1HaHuFcn--0xgZbyXwG-OK0" frameborder="0" allowfullscreen></iframe> |

</html> | </html> | ||

Revision as of 14:07, 1 July 2015

Contents

“Morphodynamical approaches for fabrication and interactive design”

Keywords: fabrication, Actuation systems, Kinetic systems, 3d printing, laser cutting, Grasshopper, Optimization.

Teachers: Gary Chang, Pablo Baquero, Effimia Giannopoulou

Abstract

Computational tools have given architects high variety of possibilities in design, meanwhile material properties investigations have a lot of potential especially in transitions of scale, patterns, structure, curvature and porosity variations. It is been difficult to construct complex geometries from smaller towards bigger scales, particularly with the current digital fabrication machines, the new methods should be re-established.

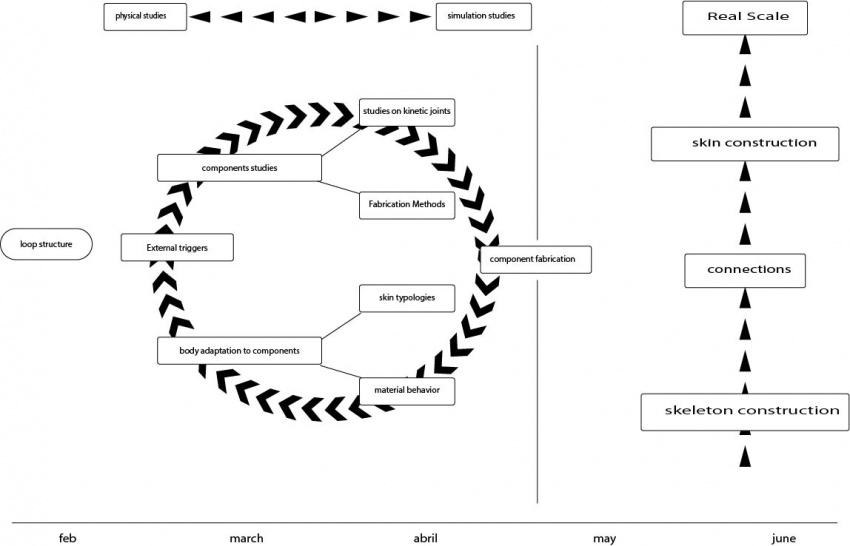

The main goal of this workshop is to develop morphodynamic techniques for a skin that would engage the traditional framework of parametric design processes using simulation strategies for dynamic formations. Design interactivity and fabrication strategies will be embedded deeply in the formation of design, through a set of local interactions on complex geometry systems.

Besides of parametric and computational tools for finding typologies of joints and assemblages; material simulations will be applied for fabrication time and optimization, enhancing the production workflow according to design complexities.

Objectives

The objective of the workshop is collaborate and teach methods of expanding a series of morphologies and its components across a skin to be attach to the main Loop skeleton, taken in count the adaptive kinetics capable of spatial modulation and response to environmental stimuli. The emphasis of the project is on the nature of systems in the built environment and their capacity of adaptation. Elements, structure, surface and performance of this networked kinetic system are designed as integrated layers that make up a construct capable of accommodating dynamic nature of human occupation.

Agenda

Tuesday April 21,

10:30 Simulation Tutorials

Simulation of project with loop structure

5:00 pm End of the day group discussion

Wednesday April 22,

10:30 Tutorials, Define Component geometry and Material.

11:30 “ TSM Material behavior simulations”, Nelson Montas.

5:00 pm End of the day group discussion

Thursday, April 23,

10:30 - 12:30 Tutorials, Define Proliferations and adaptation.

Millipede, “ Component Design Optimization 2d-3d ”. Effimia Giannopoulou.

5:00 pm End of the day group discussion

Friday, April 24,

10:30 - 12:30 Tutorials, Fabrication strategies

2:00 Final discussions with Nimish

Assign Prototypes tasks

Monday, May 4,

10:30 Prototypes review

links as references:

http://dl.acm.org/citation.cfm?id=1935716

http://www.interactivefabrication.com/blog/sketch-furniture/

http://code.arc.cmu.edu/

http://www.modrobotics.com/

http://www.swissdesignnetwork.org/index.php/33-sdn-news/80-summer-school-in-digital-fabrication-and-interaction-design

http://dspace.mit.edu/handle/1721.1/65545

http://epljournal.edpsciences.org/articles/epl/abs/2014/21/epl16643/epl16643.html

http://www.angelfire.com/ma4/bob_wb/tenseg.pdf

http://dspace.mit.edu/handle/1721.1/59192

http://www.selfassemblylab.net/SelfFoldingSurfaces.php

http://www.nature.com/srep/2014/141211/srep07422/full/srep07422.html

http://www.sciencedirect.com/science/article/pii/S0010448514000141

Inspiration

Controled by Muscle Wires

Controled by Servo motors

Controled by the wind